We provide a wide variety of pre-engineered, and custom robotic systems that are perfectly suited to the needs of any manufacturer. Being affordable, and having a small footprint these machine tending solutions are a good fit for anyone looking for fast, reliable automation.

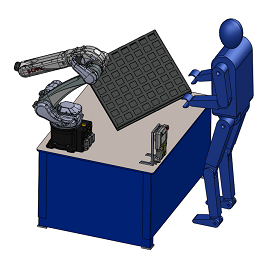

TS-1 Tray System

Lowest entry price unit. Typically used to free operator to do other jobs around the shop while machine is running. Highly flexible / fast to change over even for novice users. Fast and simple moves from one machine to another.

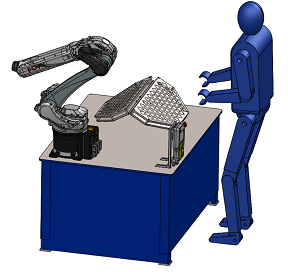

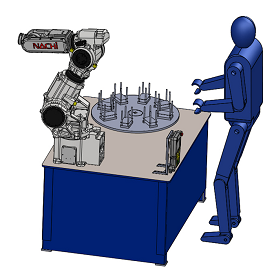

RT-2 Rotary Tray

Often used on parts that require secondary operations, inspections, and pack out. Takes all the features of the TS-1 but keeps the process running. Operator unloads finished parts while the process keeps running, packs out (etc.) and loads unmachined parts for next batch. Frees operator to do many other tasks.

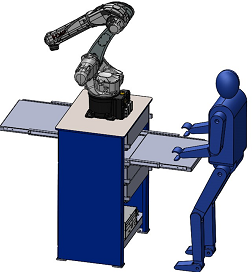

DS-3 Drawer Unit

Building on the ideas of the RT-2 unit only more parts capacity. Process never stops, and one operator can oversee up to 12 centers. A real labor saver.

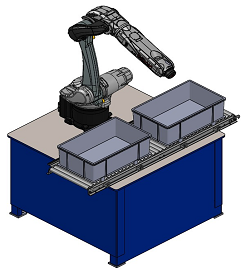

CV-1 Conveying Transport

Used for long runs. Parts are presented to the robot in an array tray. The tray is indexed and locked to the pick station. The robot picks from the tray and returns finished parts to a second tray for outfeed. The robot can use optional vision package to orient and find non-oriented parts located within the tray.

PS-10 Power Stacker

Typically used for larger batches, parts are loaded on a indexer with up to 10 stations holding many parts per stack, finished parts are re-stacked in an empty station. The operator loads parts into each station and the PS-10 runs unattended until all stations are complete.